Explosions- druckentlastung

Explosionsberstscheiben sind oft die wirtschaftlichste Explosionsschutzmethode. Sie entlassen den Druck und die Flammen einer Deflagration aus dem Behälter, damit der Gesamtdruck unter dem Konstruktionsdruck des Behälters bleibt.

Funktionsweise der Explosionsdruckentlastung?

Funktionsweise der flammenlosen Explosionsdruckentlastung?

Wann wird die Explosionsdruckentlastung eingesetzt?

Die Explosionsdruckentlastung ist eine zuverlässige Schutzmethode, wenn der Behälter:

- Im Freien steht.

- Im Innenraum steht, aber in der Nähe einer Wand, um die Deflagration mit einem Entlastungskanal nach außen zu leiten.

- Eine ausreichend großeOberfläche hat, um dieerforderliche Anzahl vonBerstscheiben zu montieren

- Materialien verarbeitet, die unbedenklich in die Atmosphäre gelangen dürfen.

Wenn die Flammen nicht an einen sicheren Ort abgeleitet werden können, kommen auf den Berstscheiben häufig Vorrichtungen zur flammenlosen Explosionsdruckentlastung zum Einsatz, um die Flammen zu löschen und Sekundärexplosionen zu verhindern.

Design des Entlastungssystems von Fike

Jedes Explosionsdruckentlastungssystem von Fike ist auf das spezifische Gefahrenrisiko sowie die individuellen Anwendungs- und Unternehmensanforderungen des Kunden zugeschnitten. Dabei werden Parameter wie Risiko, Anlage und Standort, Verschaltungen, Betriebsbedingungen und geltende Vorschriften berücksichtigt. Fike bereitet ein vollständiges Systemdesign vor. Dabei werden die folgenden Entlastungsparameter durch qualifizierte Mitarbeiter berechnet:

- Größe, Entlastungsdruck, Anzahl und Art der Berstscheiben und flammenlosen Druckentlastungsvorrichtungen, falls eingesetzt.

- Einbauposition in Ihrer Anlage.

- Auswirkung von Flammen und Druck im Außenbereich.

- Rückstoßkräfte auf die verarbeitende Anlage.

Diese Daten können außerdem nützlich sein zur:

- Prüfung, ob der Platz der Anlage zum Anbringen von Berstscheiben ausreicht.

- Prüfung, ob der Platz ausreicht, um eine Sicherheitszone (für die sichere Entlastung von Flammen und/oder Druck) zu implementieren.

- Orientierung für das Team oder den Vertragspartner bei der mechanischen Montage.

- Bewertung der Widerstandsfähigkeit Ihrer Anlagenteile gegenüber den bei einem Explosionsereignis auftretenden Rückstoßkräften.

Das finale Dokument zum Systemdesign kann Ihren anderen Unterlagen zum Explosionsrisiko und -schutz hinzugefügt und im Falle einer Sicherheitsinspektion vorgelegt werden.

Explosionsberstscheiben

Öffnet sich, wenn der interne Verpuffungsdruck den statischen Berstdruck der Entlastungsplatte übersteigt. Die Anzahl der Explosionsentlastungsplatten, die Größe und der Berstdruck werden auf der Grundlage des Gerätevolumens, der Stärke und der Brennstoffeigenschaften berechnet.

Standard

Funktion

Universell einsetzbare Explosionsberstscheiben für Anwendungen mit explosionsfähiger Atmosphäre, hohen Temperaturen, Vakuum oder Wechseldruck

Hauptvorteil

Ausführung in vielen, für nahezu alle Anwendungen geeigneten Größen und Geometrien

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA68-konform

Datenblatt

Hygiene

Funktion

Schützt Anwendungen mit hygienischen Anforderungen, explosionsfähiger Atmosphäre, hohen Temperaturen oder Vakuum, bei denen es auf Hygiene und geringe Produktablagerungen ankommt

Hauptvorteil

Niedrige Installationskosten durch:

- Hohe Entlastungseffizienz

- Integrierten oberen Rahmen

- Überdrehschutz

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA68-konform

Datenblatt

Hygiene+

Funktion

Für Anwendungen mit explosionsfähiger Atmosphäre, hohen Betriebstemperaturen und Bedarf an EHEDG-zertifizierten, bakterienfreien und hygienischen Berstscheiben

Hauptvorteil

Niedrige Installationskosten durch:

- Hohe Entlastungseffizienz

- Integrierten oberen Rahmen

- Überdrehschutz

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA68-konform

3A/EHEDG-zertifiziert

Datenblatt

Batteriespeicher

Funktion

Zur kalkulierbaren Ableitung von Druck und Flammen in Anwendungen mit Batteriespeichersystemen (BESS)

Hauptvorteil

Abgasanalyse und großangelegte Tests für wirtschaftliche, anwendungsspezifische Entlastungslösungen

Zertifizierungen und Zulassungen

ATEX EN14797

Datenblatt

Abgassystem von Gasmotor

Funktion

Schützt vor Explosionen im Abgassystem von Gasmotoren

Hauptvorteil

Beispiellose, leckagefreie Lebensdauer bei hohen Temperaturen, wechselndem Druck und Vibrationen in Abgasleitungen von Gasmotoren

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA68-konform

Datenblatt

Becherwerk

Funktion

Schützt vor Staubexplosionen in Becherwerken

Hauptvorteil

Niedrige Installationskosten durch:

- An Becherwerksschächte angepasste Scheibengrößen

- Hohe Entlastungseffizienz

- Installation mit Nieten, kein Schweißen nötig

- Integrierten oberen Rahmen

- Überdrehsicherung enthalten

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA68-konform

Datenblatt

Geräte zur flammenlosen Druckentlastung

Wird über einer Explosionsentlastungsplatte angebracht und enthält einen Flammenfilter, der die Explosionsflammen löscht, während der Explosionsdruck in die Atmosphäre abgeleitet wird.

Standard

Funktion

Universell einsetzbares Gerät für Anwendungen mit feinen, groben, faserförmigen und schmelzenden organischen Stäuben.

Hauptvorteil

Geringe Auswirkungen auf die Betriebsplanung:

- Sehr geringer Sicherheitsabstand erforderlich

- Keine Einteilung in externe Gefahrenzonen erforderlich

- Keine Einschränkung durch vorhandene Gefahrenzonen

Zertifizierungen und Zulassungen

ATEX EN14797-zertifiziert

NFPA 68-konform

Datenblatt

Premium

Funktion

Aufgrund der Ausführung in Edelstahl für Metallstäube, korrosive Umgebungen und den Lebensmittelbereich geeignet

Hauptvorteil

Geringe Auswirkungen auf die Betriebsplanung:

- Sehr geringer Sicherheitsabstand erforderlich

- Keine Einteilung in externe Gefahrenzonen erforderlich

- Keine Einschränkung durch vorhandene Gefahrenzonen

Zertifizierungen und Zulassungen

Auf Anfrage ATEX-zertifiziert

FM-zugelassen

NFPA 68-konform

Datenblatt

Becherwerk

Funktion

Schützt Becherwerke vor Staubexplosionen

Hauptvorteil

Niedrige Installationskosten durch:

- Kompaktes Design mit an die Becherwerkschächte angepassten Scheibengrößen

- Hohe Entlastungseffizienz

Zertifizierungen und Zulassungen

ATEX-zertifiziert

NFPA 68-konform

Datenblatt

Abgassystem von Gasmotor

Funktion

Für Abgassysteme von Gasmotoren, insbesondere in bemannten oder maritimen Anwendungen

Hauptvorteil

Beispiellose, leckagefreie Lebensdauer bei hohen Temperaturen, wechselndem Druck und Vibrationen

Zertifizierungen und Zulassungen

NFPA 68-konform

Datenblatt

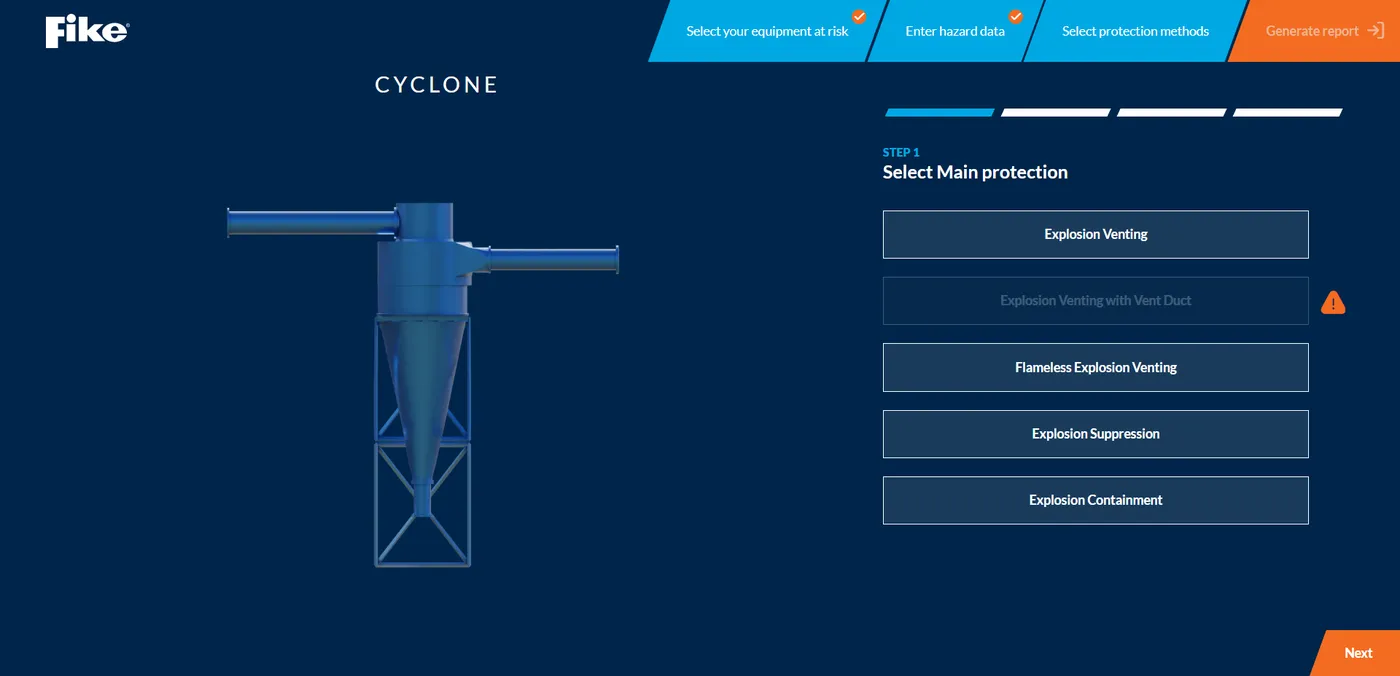

Anlagenspezifische Prüfung der Explosionsdruckentlastung

Anhand der Prüfung wird ermittelt, welche Schutzverfahren für Ihre Anlage geeignet sind. Berücksichtigt werden dabei u. a. Faktoren wie Staubart, Größe und Standort. Die Ergebnisse werden Ihnen im Anschluss per E-Mail für Ihre Unterlagen zugesendet.

Welche Vorteile hat die Explosionsdruckentlastung?

Die Explosionsdruckentlastung ist eine Form des passiven Explosionsschutzes, d. h. die Vorrichtung wird durch den Deflagrationsdruck selbst aktiviert. Dies ist die kostengünstigste Lösung, da sie nicht auf ein elektronisches Erkennungs- und Steuersystem angewiesen ist.

Darüber hinaus kann die Explosionsdruckentlastung bei Industrieanlagen verschiedener Größen mit relativ problemloser Installation und minimalem Instandhaltungsaufwand eingesetzt werden.

Hat die Explosionsdruckentlastung auch Nachteile?

Die Druckentlastung ist zwar eine kosteneffiziente Lösung für den Explosionsschutz, vor ihrem Einsatz gilt es jedoch, einige Aspekte zu bedenken.

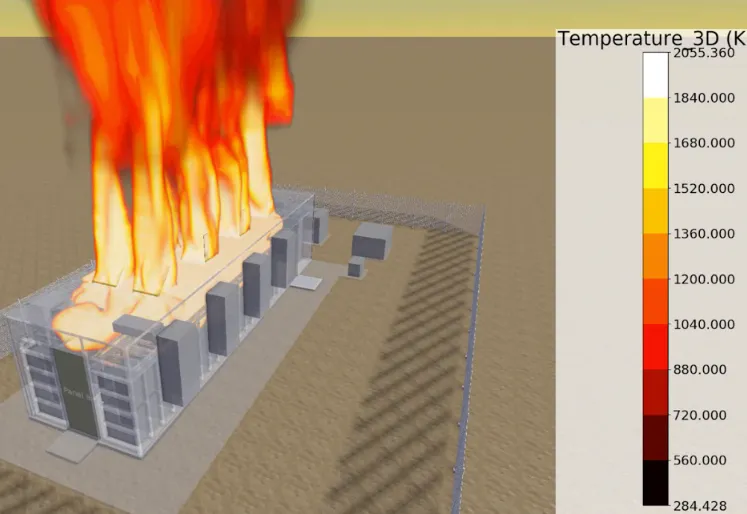

Mit dieser Lösung können Explosionen nicht verhindert und Flammen nicht gelöscht werden. Das Volumen des entstehenden Feuerballs kann bis zu 75 Mal größer sein als das Gehäuse. Daher muss der Entlastungsweg in einen sicheren Bereich ohne Personenverkehr führen. Nach der Explosion können außerdem Brände entstehen, sodass häufig Brandunterdrückungssysteme benötigt werden. Vor Wiederaufnahme der Produktion müssen eventuelle Schäden an der Anlage repariert und die Berstscheiben ersetzt werden.

Zur Vermeidung dieser Nachteile wird häufig die Explosionsunterdrückung als Alternative zur Explosionsdruckentlastung eingesetzt.

Worin bestehen die Unterschiede zwischen Berstscheiben und Explosionsklappen / Entlastungsventilen?

Explosionsklappen sind schwerer als Berstscheiben und beanspruchen oft eine größere Fläche. Im Explosionsfall neigen sie dazu, bei Staub mit höheren Kst-Werten (Schwere der Staubexplosion) zu zersplittern. Ihr Öffnungsdruck steigt in der Regel im Laufe der Zeit aufgrund von Korrosion und Schmutz an, sodass sie regelmäßig gewartet werden müssen. Schließlich kann das Wiederverschließen von Klappen und Ventilen zu einer Implosion des Behälters führen, wenn sich die Verbrennungsgase nach der Explosion abkühlen.

Ein Vorteil von wiederverschließbaren Klappen und Ventilen ist jedoch, dass sie das Eindringen von frischem Sauerstoff verhindern, der das Feuer nach der Explosion aufrechterhalten könnte.

Wer kann Explosionsdruckentlastungen für meinen speziellen Prozess entwerfen?

Das Expertenteam von Fike liefert Lösungen für nahezu alle Anwendungen. Es ermittelt nicht nur, ob die Explosionsdruckentlastung eine praktikable Schutzstrategie für Ihr spezielles industrielles Verfahren ist, sondern führt auch folgende Berechnungen durch:

- Größe, Berstdruck, Anzahl und Typ der Berstscheiben

- Einbauort der Berstscheiben

- Auswirkung von Flammen und Druck im Außenbereich

- Rückstoßkräfte