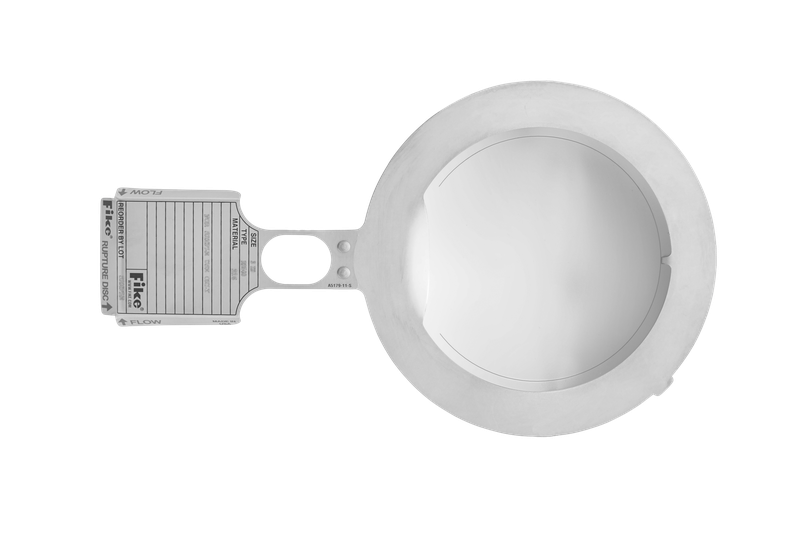

Fike recently expanded its RD540 rupture disc sizes to include 6- and 8- inch discs, while still maintaining a low burst pressure range of 7 PSI down to 1.75 PSI. This expansion makes the same reverse-acting rupture discs suitable for more applications, especially sensitive equipment.

“The new 6- and 8- inch sizes are a game changer,” said Ben Menke, Fike Regional Sales Manager. “They let us apply the same high-performance solution to larger process systems without switching to a different product line. That helps us avoid inconsistency and prevents training gaps for our teams and our customers.”

The RD540 reverse-acting discs are commonly used for low burst pressure protection in hygienic industries, which often rely on glass-lined vessels to store vapors and gases. Demand for these discs is especially high in Europe, where strict regulations require rupture discs to burst below 0.5 bar, or 7 PSI.

Reverse-acting discs

Reverse-acting discs are designed to buckle and burst in a controlled and predictable way. Since the metal used for these discs is compressed and not stretched, they are effective and reliable for sensitive applications in industries like pharmaceuticals, biotechnology, and food processing.

Before reverse-acting rupture discs were used, graphite discs were often chosen to protect sensitive equipment. However, because graphite discs fragment upon rupture, Fike has spent decades advancing its reverse-acting rupture disc technology to completely eliminate fragmentation issues and deliver clean solutions.

“Now you can get a metal rupture disc that won’t fragment. Just take it out and put another one in,” said Michael Krebill, Fike Principal Engineer, who has been a key contributor in shaping Fike’s modern rupture disc design and evolution. This simplicity reduces downtime and maintenance costs while protecting both equipment and employees.

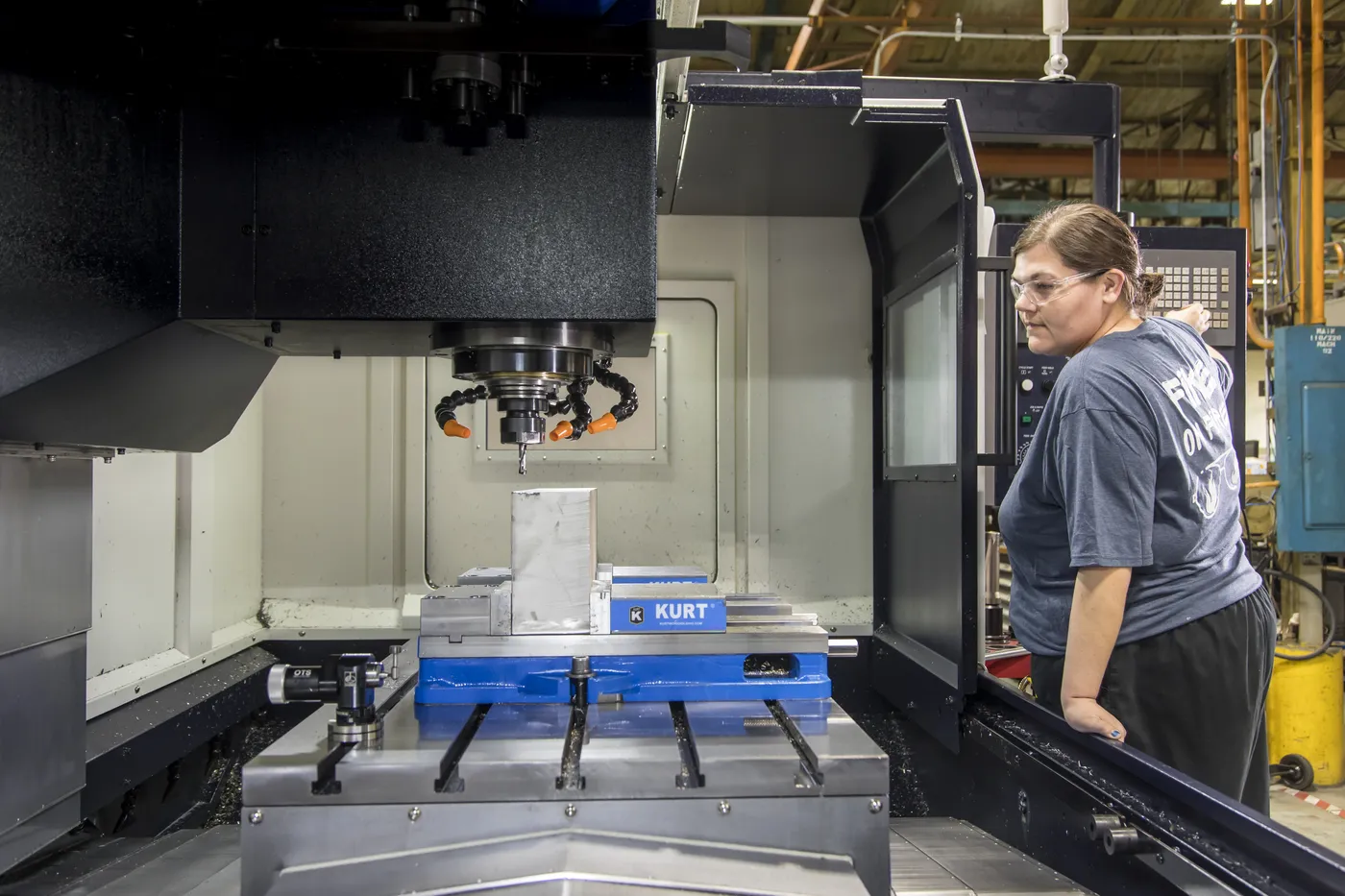

Evolution of Manufacturing methods

The evolution of Fike’s reverse-acting disc technology reflects the ongoing focus on precision and reliable performance. For example, in the early days Fike used scoring to create a controlled burst point on each disc. However, as equipment across the industries evolved, we advanced our manufacturing techniques. This led to the development of milling, a technique still used for metals 0.008” and thicker that cuts halfway through the material without introducing stress. When stress is added to the metal, it can cause the disc to weaken over time.

Finally, Fike began integrating the use of femtosecond laser ablation on various discs. Laser ablation vaporizes metal in micro layers, creating precise cuts for the designated weak spots on discs to ensure the disc performs and opens precisely as they are engineered.

Why does Fike continue to innovate pressure relief solutions?

Fike is developing technical systems and design software to support pre-engineered disc configurations on a global scale. By using reversal curves and digital disc modeling, we've created a system that can quickly generate accurate burst pressures without a lengthy design or delivery process. We have mastered a consistent and efficient manufacturing approach that’s accessible across all of our global locations.

“We’re creating all of these tech systems to be used and transferring them to our Europe office,” Krebill said. This step will allow global teams to reach their countries standards for pressure relief through Fike’s uniform custom design process technology.

“We used to figure it out on every order. Now, we pre-engineer everything because customers expect speed, precision and performance,” Krebill said.

RD540’s expansion represents yet another innovation in Fike’s family of rupture discs to ensure industrial processes remain safe from pressure-related hazards and that Fike always has a solution regardless of the challenge.

“From a broader perspective, I see the RD540 as a signal that Fike is continuing to innovate in niche spaces that our competitors often overlook. Our customers notice that kind of commitment, and it sets the tone for trust.”

Ben Menke