When an ignition source meets a combustible dust cloud within an enclosed space, a devastating explosion may occur.

Explosion vents are often installed on these vessels to open and safely relieve pressure and flames. How effectively a vent relieves pressure is referred to as its venting efficiency, which helps determine the proper size and quantity of events that are required to safely protect the process.

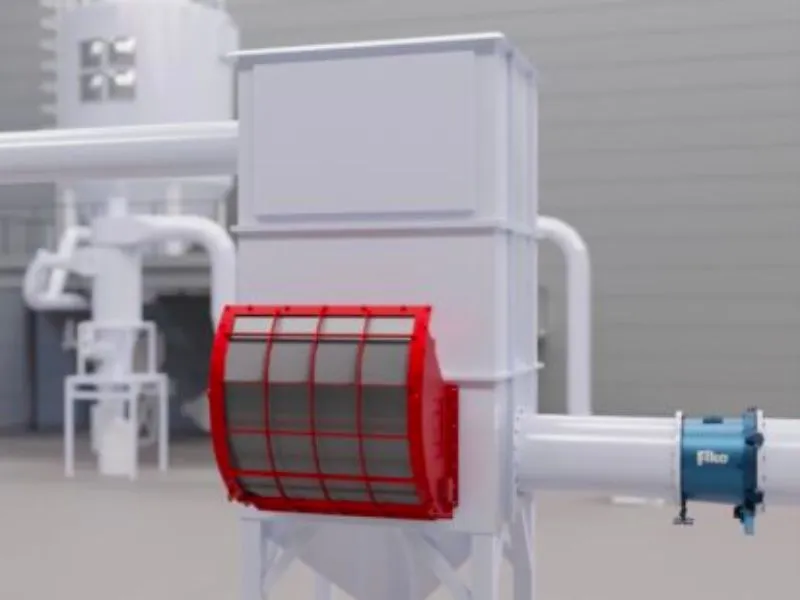

When these applications are located indoors, free venting isn't possible and flameless venting devices may often be used instead. During an explosion, the vent panel opens and a mesh filter absorbs the heat so flame doesn't extend past the device.

However, a number of particles may clog the filter, which greatly reduces its venting efficiency. This is why product clogging and several other variables must be included in the design of a flameless venting system. Otherwise, the resulting explosion pressure might become higher than the expected reduced explosion pressure, resulting in vessel failure.

Owners of flameless vents should be aware of these safety factors to ensure workers and the process are reliably protected. If a dust explosion were to occur because so much is at stake.