CO2 Fire Suppression Systems

Fike’s Carbon Dioxide Fire Suppression System is an effective and versatile method of fire extinguishment used to minimize downtime in industrial environments and in localized applications not possible by other forms of fire suppression.

The Fire Suppression Science Behind CO2

Because the sustainability of a fire requires fuel, heat and oxygen, removing one of these elements from the equation will extinguish the fire. Fike’s CO2 Fire Suppression System reduces oxygen to extinguish most fires, including:

- Surface or “flash” type fires: oils, paints, etc.

- Deep-seated or “smoldering” type fires: paper, baled cotton, clothing, etc.

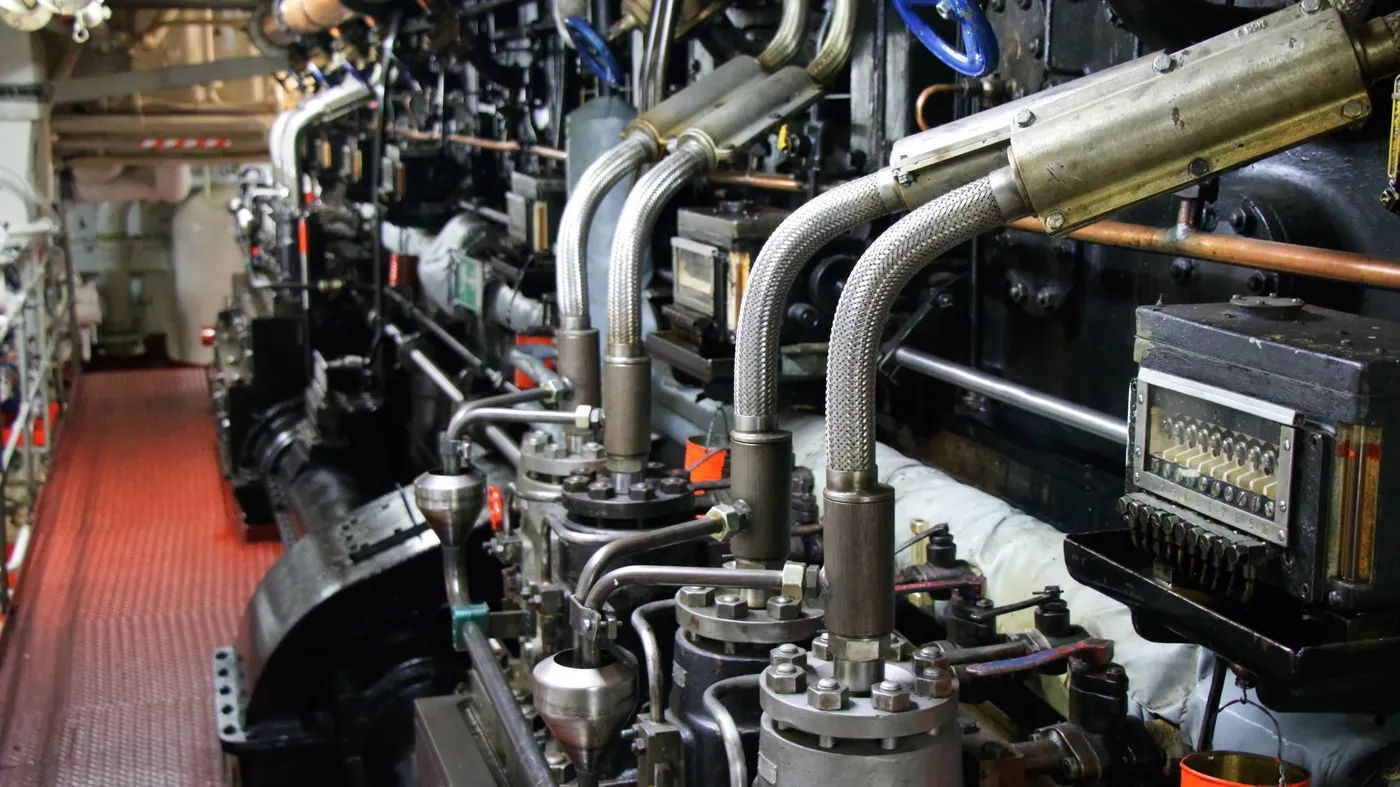

- Localized applications: ship engines, dip tanks, oil-coated surfaces.

Retaining the agent within the protected space reduces the fire’s ability to re-ignite. In addition, CO2 has a cooling effect on the surrounding atmosphere that benefits fire extinguishment. Because carbon dioxide is a gas, no cleanup is required after a Fike CO2 fire suppression system discharges.

It is approximately 50 percent heavier than air, and is normally present in the atmosphere at about 0.03 percent by volume. When applied to a fire, CO2 provides a heavy blanket of gas that reduces the oxygen level to a point where combustion cannot occur.

Localized Applications

CO2 is the only agent that’s been tested and validated for localized application discharge. This allows reliable suppression for specific hazard areas, rather than requiring a total flood of the space.

Flammable liquids, gases and shallow solids may be protected where the hazard is not enclosed or where leakage prohibits the use of a total flooding system. Some examples of such hazards are dip tanks, quench tanks, spray booths, oil-filled transformers and hydraulic pump/reservoir systems.

When Is The Use Of CO2 Effective?

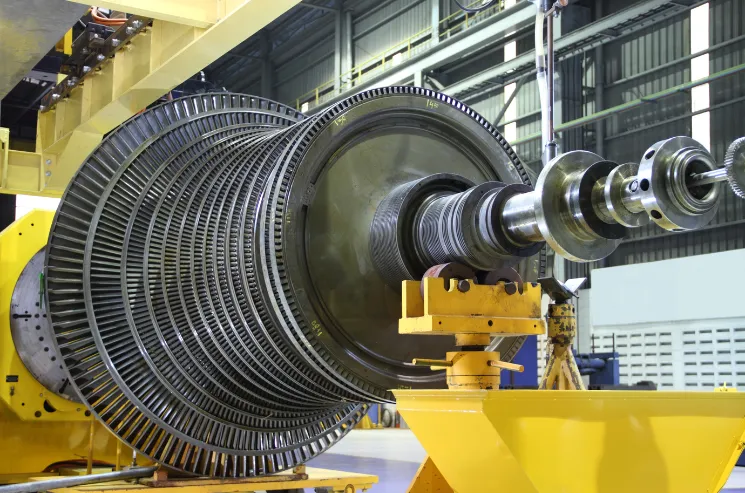

CO2 is effective in areas where flammable solids and liquids are present. Fires in these hazards spread very rapidly. Deep-seated fires associated with hazards such as electrical equipment, bulk record storage, dust collectors, and ductwork are equally well protected with CO2. A fixed-pipe system that is engineered specifically for a particular hazard, and actuated automatically, assures the early detection and rapid extinguishment necessary to prevent major losses and downtime.

Fike CO2 Systems are custom designed to protect a specific hazard or application. The quantity of CO2 and the method of application required for the protection of a specific hazard are determined by the system designer, but the final design must be based on the materials or product involved. NFPA 12 and this design manual are used as guides to determine the appropriate design parameters. Fike CO2 systems can be actuated automatically, pneumatically or manually. Automatic systems incorporate fire detectors and system control panels, along with electric and mechanical/manual releases that are located in the hazard area. When activated, they send a signal to the control panel to release the CO2 into the hazard. Mechanical/manual actuator(s) are generally located at, or near, the CO2 cylinder storage area. Automatically actuated systems are electrically operated and always incorporate an emergency manual override feature and standby power supply.