Explosion Suppression Systems

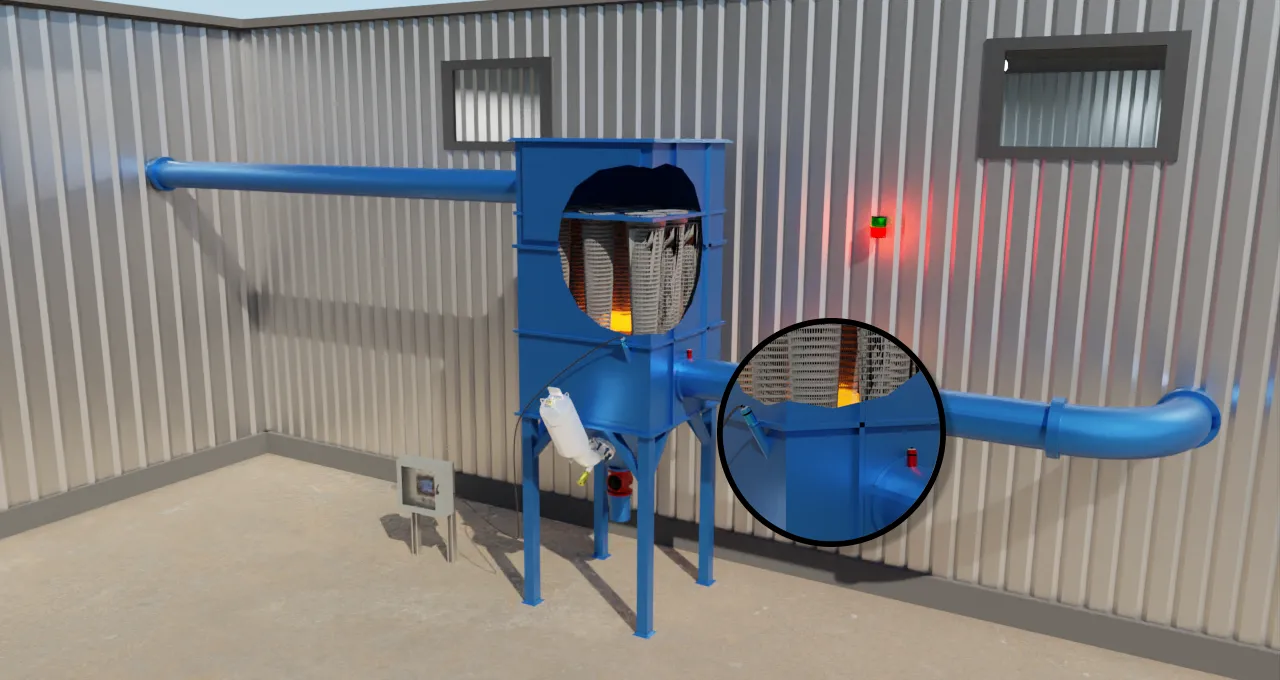

Fike explosion suppression systems detect a combustion reaction in its incipient stage and inject chemical suppressant agent into the process to quickly stop the development of pressure and flames before the deflagration becomes catastrophic.

How Does Explosion Suppression Work?

Fike HRD

Active Suppression System - High Rate of Discharge

Fast Suppression

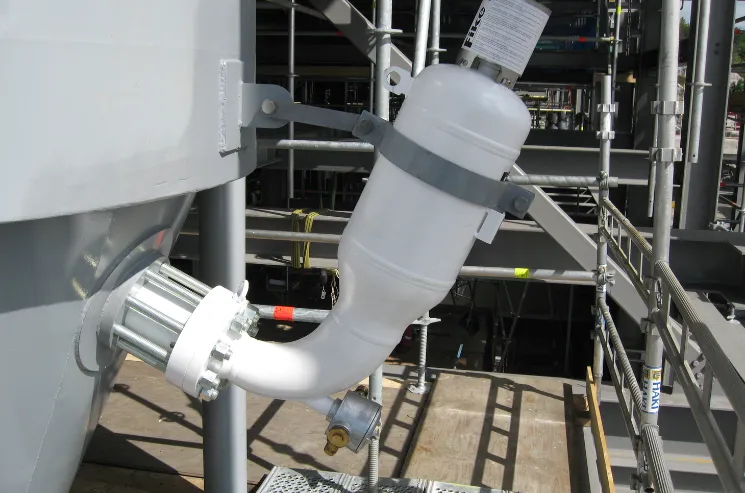

Patented container and nozzle designs minimize flow restrictions; gas cartridge actuator opens the bursting disc within 1 millisecond.

Spreader Nozzles

Includes Standard, Telescopic and Short-Throw nozzles to meet the application's unique demands and ensure high performance.

Hygienic Capabilities

Available with food-grade suppression agents and hygienic installation flanges.

Lockout - Tagout

HRD Lockout Assembly prevents accidental discharge during cleaning or maintenance.

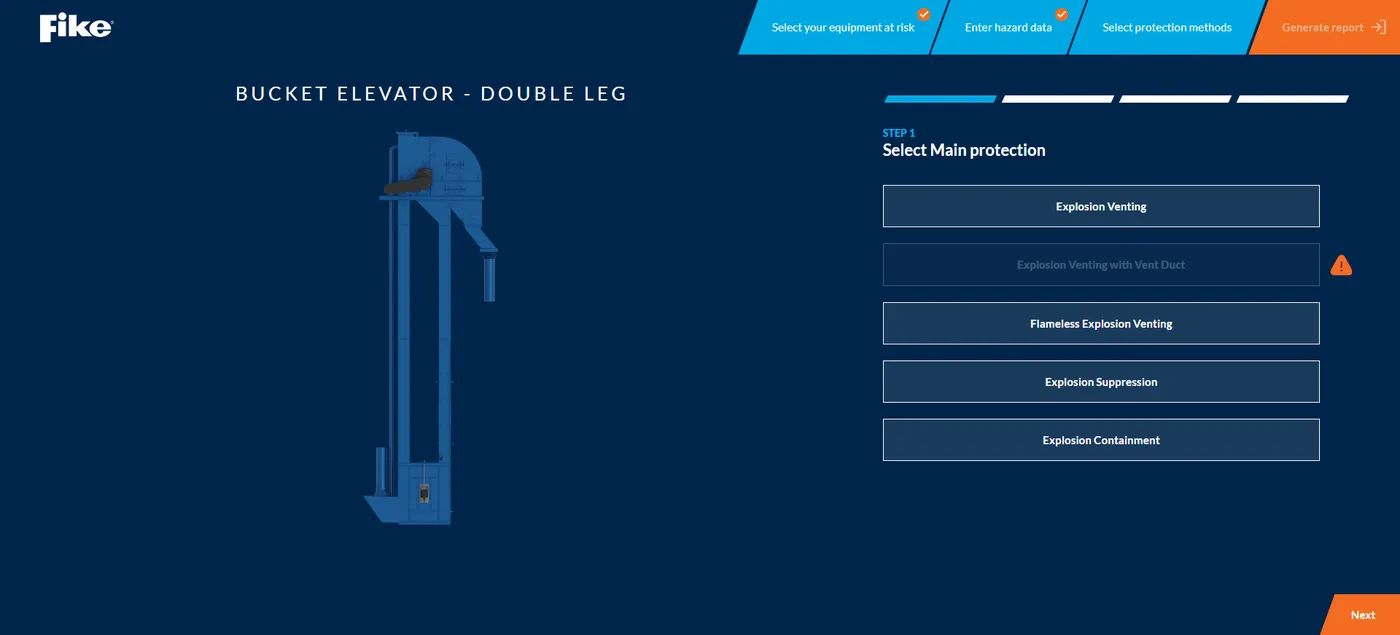

Test Explosion Suppression On Your Equipment

This easy-to-use tool helps confirm the safest and most cost-effective protection methods for your equipment based on its handled dust type, size, location and more. Results and recommendations are then emailed to you for your records.

Fike Suppression System Design

Each Fike explosion suppression system is custom designed specifically to mitigate your hazard risk and meet the needs of your application and business. This process is completed based on your unique combination of hazard type, equipment and its location, interconnections, operating conditions and regulations. As part of this design process, Fike prepares a full system design where the following suppression parameters are calculated by qualified personnel:

- Detector and suppressor type, quantity and installation location.

- System operating and activation settings.

- Total suppressed pressure.

This data can be used to:

- Guide your mechanical installation team or contractor.

- Evaluate your equipment’s capability to withstand the recoil forces that may arise during an explosion event.

- The final system design document can be added to your explosion hazard and protection files to be submitted in case of a safety inspection.

Once your protection systems have been selected, you may rely on Fike’s global field technicians to perform:

Installation

that precisely replicates system design drawings and is performed during a convenient time in your production schedule. Full turnkey installation is also available when required.

Commissioning

of active explosion protection systems to ensure that electrical, PLC and other connected processes work as intended.

Maintenance

which may include quarterly inspections to maintain compliance or emergency maintenance when you need us most. Flexible service level agreements provide guaranteed response times according to your business needs.

Explosion suppression is often required when:

Explosion venting to a safe location or flameless venting is not possible.

Release of hazardous product is toxic to plant personnel or the environment.

The equipment doesn't have enough available surface area to support the necessary explosion vent panels.

The ability to quickly resume production after an explosion is required.

What are the advantages of explosion suppression?

- Immediate extinguishment and halting of the beginning explosion; conversely, venting and other passive protection methods allow the explosion to fully develop before activating.

- Low risk for flame propagation into connected ducts.

- Low risk for post explosion fire.

- Minimal equipment damage, fast reset and fast resuming of production process.