Pressure Relief Valve Isolation with Fike Rupture Discs

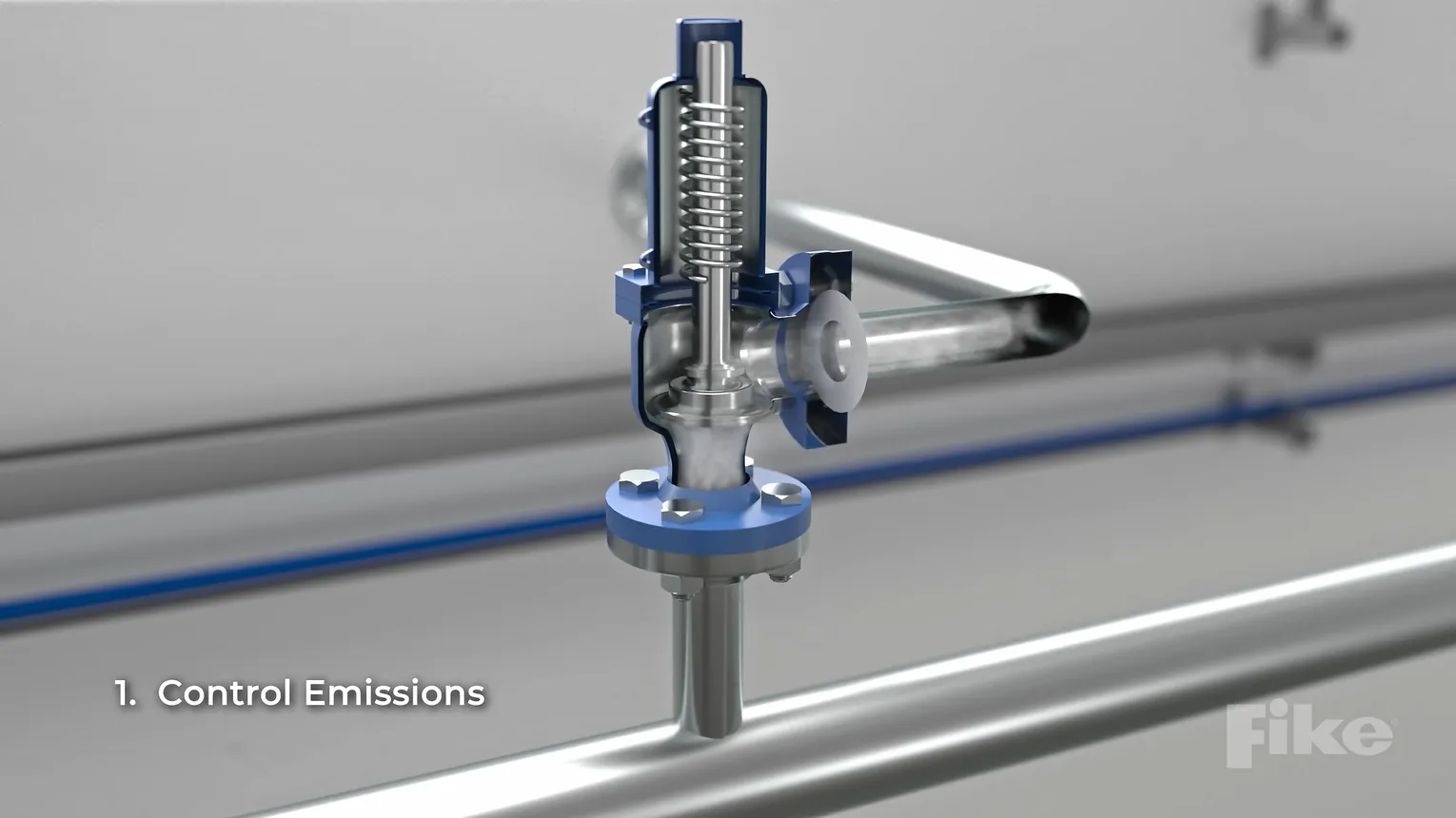

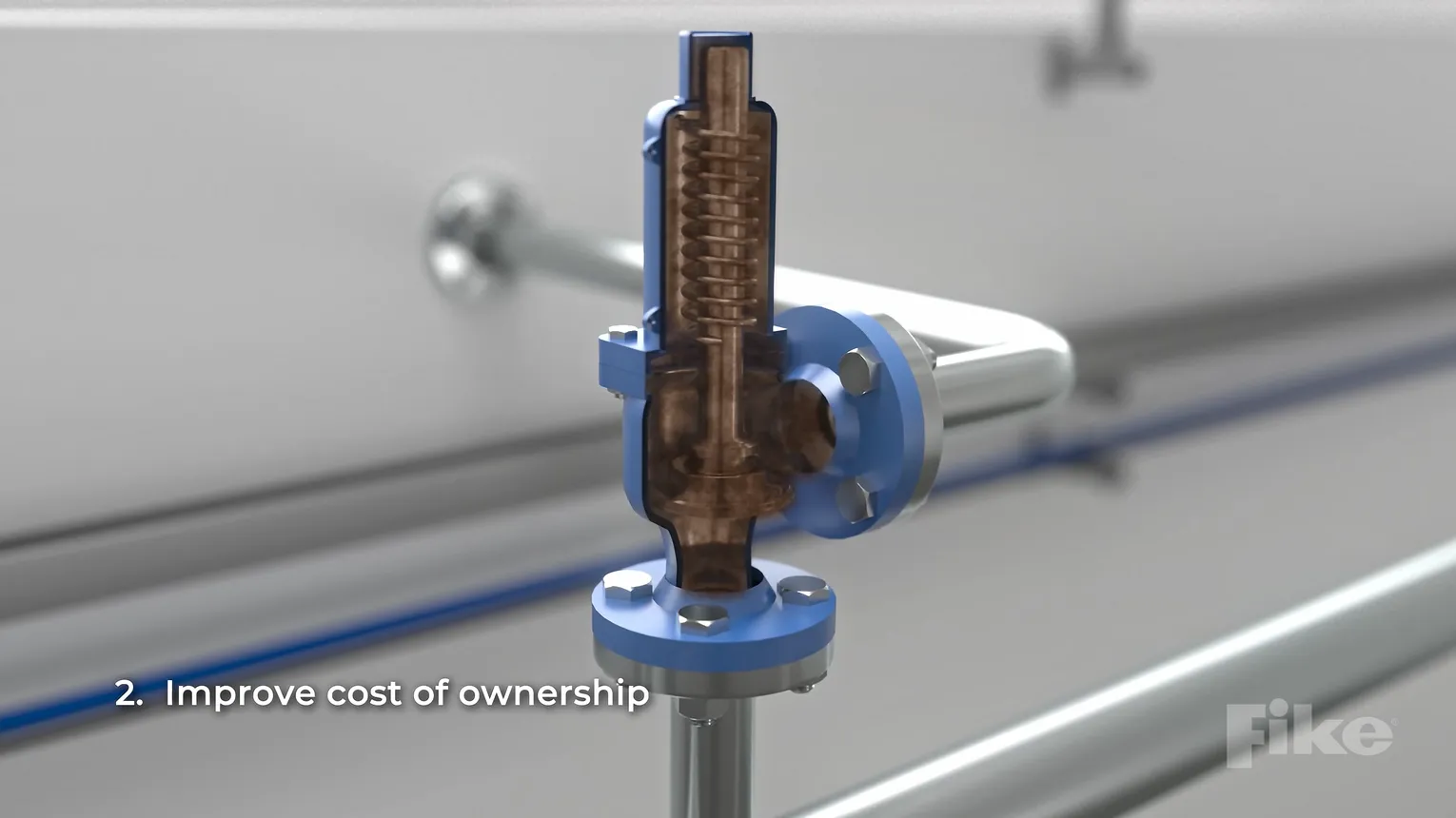

Did you know that by installing rupture discs upstream of pressure relief valves (PRVs), you can reduce unwanted emissions, protect against downtime and improve overall cost of ownership?

Pressure Relief Valve Isolation with Fike Rupture Discs

While PRVs are commonly used throughout industrial manufacturing facilities, rupture discs may be preferred instead when sudden pressure spikes may occur, leak tightness is required or the process media is corrosive.

Rupture discs are also often used in series with PRVs to realize the inherent advantages of both devices.

By using the two pressure relief devices together, many of the shortcomings of PRVs are avoided:

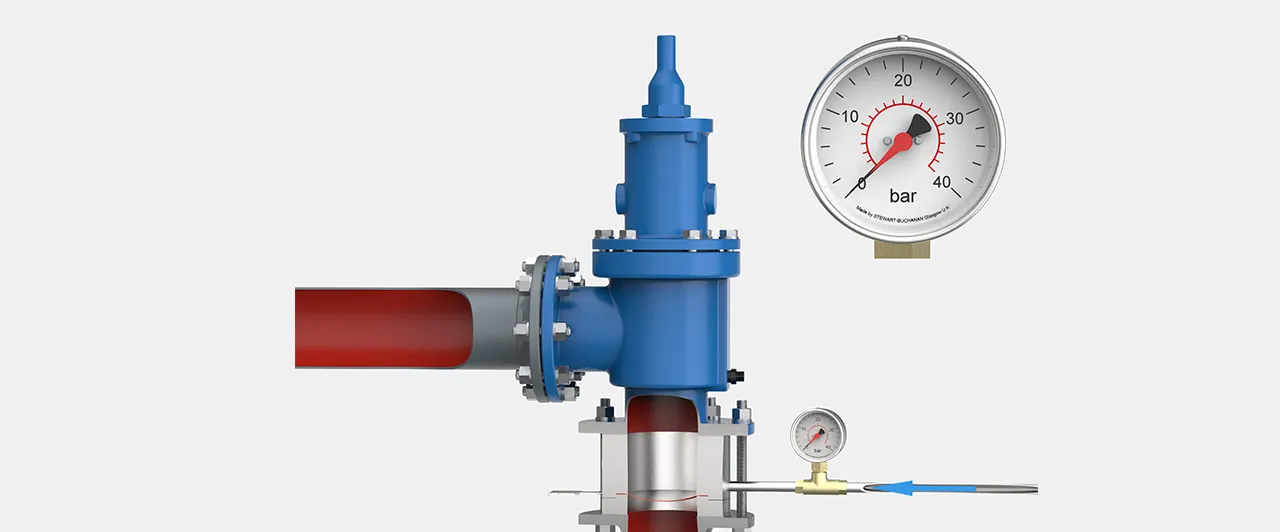

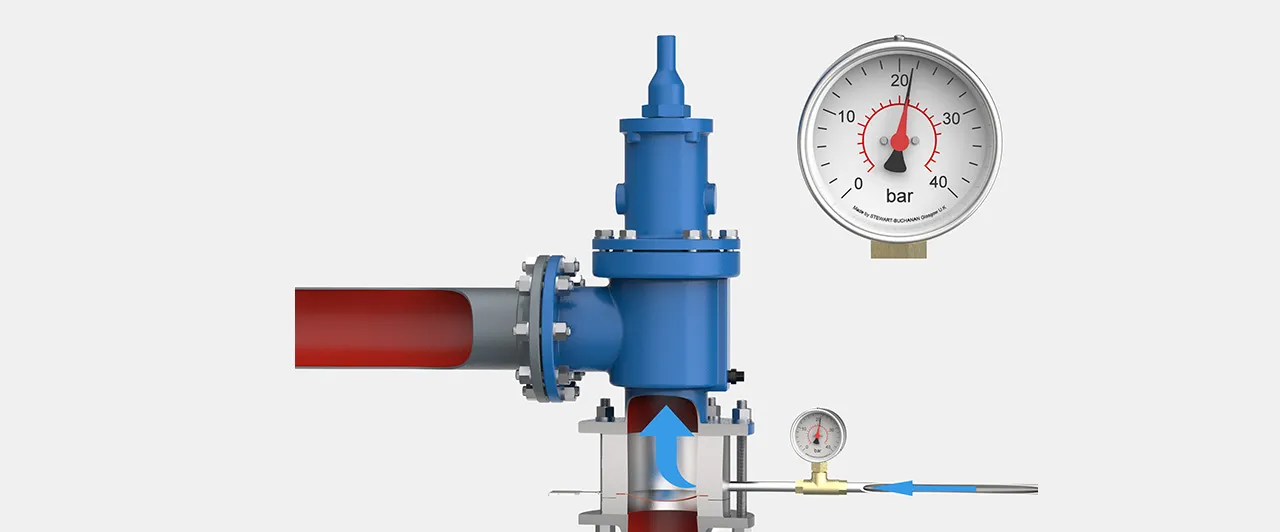

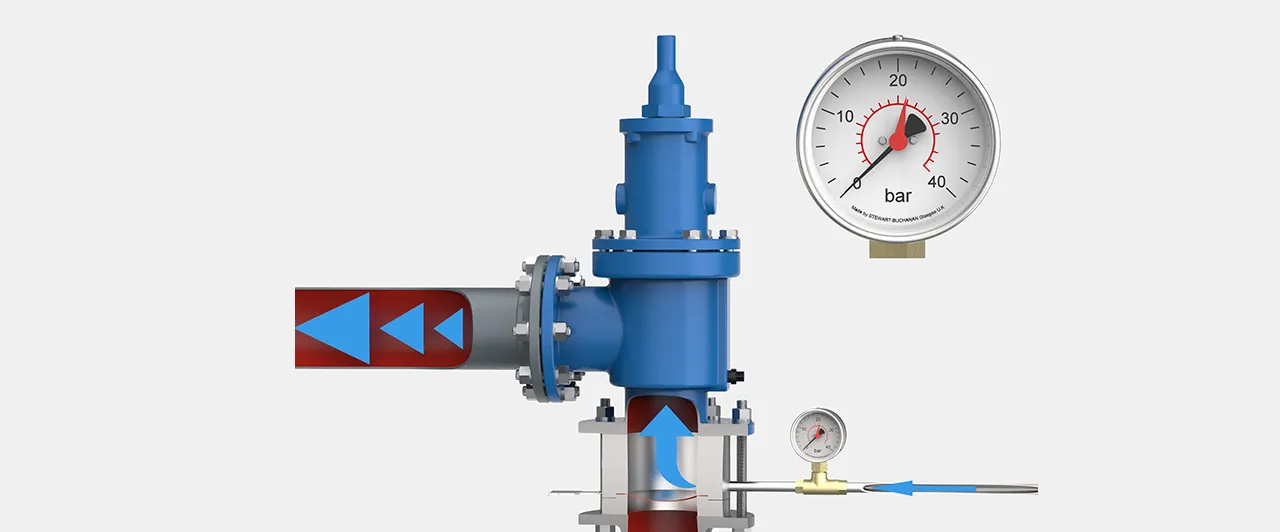

How In-Situ Testing Works with Rupture Discs and PRVs

Fike rupture discs can be trusted to reliably isolate PRVs and provide the advantages listed above due to their:

Superior Reliability

Features our highest operating ratio of 95 percent, allowing production facilities to run at full capacity without worry of altering burst pressure.

Extraction Scoring

Opening feature is laser-ablated or milled, not scored, providing an ultra-reliable line of weakness not found in work-hardened scoring methods.

High Life Cycle

Superior performance even for extreme process cycles of full vacuum to 95 percent burst pressure results in a less downtime for changing rupture discs.

Backpressure/Vacuum Resistance

Concave surface faces the process side and can withstand full vacuum without added support; also ideal for in situ testing of pressure relief valves.

Pressure Relief Consultancy

In addition to being one of the world’s leading rupture disc manufacturers, Fike also assists our customers with a number of pressure relief consultancy services, including PRV isolation with rupture discs.

Our global team is prepared to visit your facility and identify where your process could take advantage of using rupture discs in series with your PRVs, and discuss numerous other opportunities to improve the cost of ownership of your pressure relief system and protect your process from downtime.