Berstscheiben zur Druckentlastung

Erfahren Sie, warum Kunden seit mehr als 75 Jahren auf die Berstscheiben von Fike vertrauen. Diese bersten genau dann, wenn sie zur Druckentlastung benötigt werden und es darum geht, Mitarbeiter und das Unternehmen vor einer potentiellen Katastrophe zu schützen.

Berstscheiben von Fike

Die Berstscheiben von Fike schützen Ihre Geräte vor druckbedingten Ausfallzeiten und Schäden.

G2 Premium

Produktname

Fike RD500 Atlas®, RD520 Axius®, RD540

Kategorie

Umkehrberstscheibe

Funktion

Mit seiner urheberrechtlichen geschützten Technologie fertigt Fike Umkehrberstscheiben mit hohem Betriebsdruckverhältnis, hoher Zyklus- und Gegendruckbeständigkeit sowie geringen Bersttoleranzen.

Datenblätter

Hygienisch

Produktname

Axius® SC

Kategorie

Umkehrberstscheibe für Hygieneanwendungen

Funktion

Frei von Vertiefungen, in denen sich Verunreinigungen festsetzen können, entwickelt mit CIP/SIP-Funktion; ideal für Anwendungen in der Biotechnologie, Pharmazie sowie Lebensmittel- und Getränkeindustrie.

Datenblätter

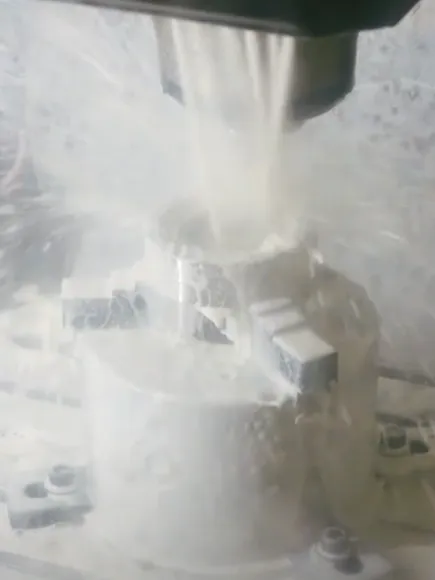

Maßgefertigt

Kategorie

Kundenspezifisch und Extruderberstscheiben

Funktion

Standardberstscheiben und -halterungen von Fike, die für Ihre speziellen Anforderungen modifiziert oder komplett überarbeitet werden.

G2-Technologie von Fike

Berstscheiben sind Vertrauenssache. Daher arbeitet Fike seit 75 Jahren Tag für Tag daran, höchste Betriebsdruckverhältnisse, geringe Bersttoleranz und maximale Lebenszyklen zu erreichen.

Dieses Engagement mündete in die Entwicklung von Fikes patentierter G2-Technologie, mit der die zuverlässigsten Berstscheiben aller Zeiten hergestellt werden.

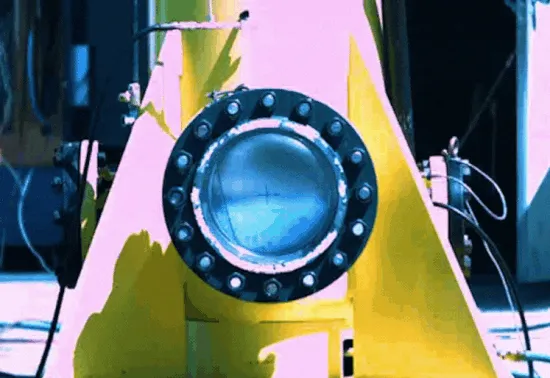

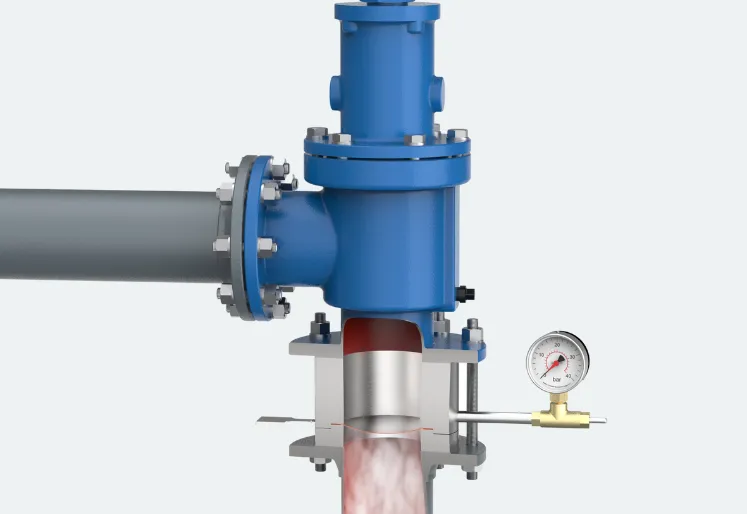

In Kombination mit Sicherheitsventilen

Die ValveGuard-Strategie von Fike kombiniert Berstscheiben mit Sicherheitsventilen (PSVs), um flüchtige Emissionen zu verhindern, PSVs vor Verstopfung und viskosen Medien zu schützen und vieles mehr. All diese Faktoren reduzieren den Bedarf an kostspieligen Wartungen und verlängern die Lebensdauer der PSVs.

Hygiene- berstscheiben

Daher wurden für CIP/SIP und andere Prozesse, Hygieneberstscheiben entwickelt, die die glatteste Oberfläche aufweisen, die derzeit auf dem Markt erhältlich ist.

Maßgeschneiderte Lösungen

Manche Herausforderungen im Bereich Druckentlastung gehen über Standardlösungen hinaus. Fike findet Lösungen für Ihre speziellen druckbezogenen Fragen und Probleme und baut dabei auf ein erfahrenes Expertenteam, ein ASME zertifiziertes Strömungslabor und unübertroffene Erfahrung.

Anwendungen

Pharmazeutische Industrie

Luftfahrt

Ölbohrinseln

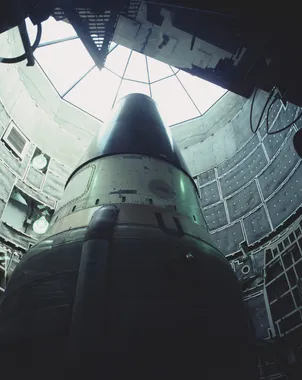

Militär & Verteidigung

In Kombination mit Sicherheitsventilen

Chemiefabriken

Luftfahrt & Satelliten

Lebensmittel- und Getränkeverarbeitung

Warum Fike?

Fike bietet Sicherheitslösungen für die Industrie und die Produkte des Unternehmens genießen weltweites Vertrauen, wenn es darum geht, Mitarbeiter, unternehmenskritische Anlagen und die Unternehmen selbst zu schützen. Doch alles begann 1945 mit der Entwicklung der ersten Sicherheitsvorrichtung, der Berstscheibe von Fike.

Seitdem hat das Fike-Team stetig daran gearbeitet, das Berstscheibenangebot auf neue Anwendungen auszuweiten, die Leistung zu perfektionieren und die Lieferzeiten zu verkürzen. Aus diesem Grund ist Fike einer der Pioniere der modernen Berstscheibentechnologie und daran wird sich auch in den kommenden Jahren und Jahrzehnten nichts ändern. Weil so viel auf dem Spiel steht.

- Niedrigere Gesamtbetriebskosten

-

Die Berstscheiben von Fike sind auf maximale Betriebsdruckverhältnisse ausgelegt und halten hohen Temperaturen und Druckzyklen stand. Sie sind in verschiedensten Materialien erhältlich und dadurch für all Ihre Prozesse geeignet. All diese Faktoren sorgen für eine lange Lebensdauer, indem sie die Zeit zwischen dem Austausch verkürzen und kostspielige ungeplante Ausfallzeiten verhindern.

- Kurze Lieferzeiten

-

Der komplette Herstellungsprozess der Berstscheiben wird von Fike durchgeführt und überwacht. Dies ermöglicht es auf kundenspezifische Anforderungen schnell zu reagieren. In Notfällen können Sie dank unserer Expressfertigung den Betrieb so schnell wie möglich wieder aufnehmen und so Ausfallzeiten reduzieren.

- Unübertroffener Support

-

Das Expertenteam von Fike steht Ihnen stets zur Verfügung, um Sie bei Fragen, Anfragen und Bestellungen zu beraten. Außerdem schulen wir unsere Vertriebspartner sorgfältig, um sicherzustellen, dass diese in der Lage sind, Sie entsprechend dem Fike-Standard zu unterstützen.

- Kundenspezifische Lösungen

-

Kundenspezifische Druckentlastungslösungen von Fike kamen bereits in kryogenen Anwendungen, Umgebungen mit hohen Hygieneanforderungen, extrem kleinen und großen Anwendungen und sogar im Weltraum zum Einsatz. Ganz gleich, wie Ihre Herausforderung aussieht - es gibt nichts, was unsere Ingenieure noch nicht gesehen haben. Sie stehen bereit, um Ihre speziellen Probleme bei der Druckentlastung mit maßgeschneiderten Produkten zu lösen.