Flameless Explosion Venting

Flameless vents may be installed over explosion vents to extinguish flames while still allowing pressure to escape, making indoor “passive” explosion protection solutions possible.

Introducing Fike FlamQuench™ III

As your explosion protection partner, you can trust Fike to not only reliably protect your workers from industrial hazards but also to protect your company’s bottom line by providing our most cost-effective solutions without sacrificing safety.

That’s why we’ve developed FlamQuench III SQ, a flameless venting system that offers greater explosion venting efficiency, potentially fewer required devices and improved cost of ownership. This is possible due to the removal of the Particle Retention Screen (PRS), which upon a deflagration improves the flameless vent’s efficiency by decreasing the amount of particulate clogging the flameless device.

FlamQuench III fills an important role by providing new and more cost-effective options when designing your explosion protection system.

FlamQuench III SQ

- Dust particles are released to the outside

- More external hazards (larger safety distance)

- Higher venting efficiencies

- Larger maximum protected volumes (Vmax)

FlamQuench II SQ

- Dust particles are retained inside vessel

- Lower external hazards (smaller safety distance)

- Lower venting efficiencies

- Smaller maximum protected volumes (Vmax)

Flameless Vents’ Effect on Venting Efficiency

An essential performance indicator for an explosion venting system is its venting efficiency, which describes how effectively it relieves pressure in a vessel during a deflagration. Flameless venting systems, however, include flame filters to make indoor venting achievable, but when the flame filter becomes clogged by burnt and unburnt particles, its venting efficiency is reduced.

If this efficiency rating isn’t properly calculated for an application in which flameless vents are installed, they may not safely relieve the deflagration pressure when called upon. For example, a flameless vent may perform very well under 500g/ m3 of cornstarch, showing an efficiency of 70 percent, but clogs very quickly under 500g/m3 of wood flour, showing an efficiency of just 40 percent or lower.

That’s why flameless venting performance cannot be described by one efficiency number but rather must be disclosed through a complex model that considers all of the factors of the process and its handled dust. Learn more about venting efficiency and flameless vents, and how Fike ensures safe system design, in the white paper below.

How Does Flameless Explosion Venting Work?

Flameless Explosion Vent Devices

Placed over an explosion vent panel and contains a flame filter to extinguish the explosion flames while the explosion pressure is discharged into atmosphere

FlamQuench™ II SQ

Function

General purpose flameless venting device for fine, coarse, fibrous and melting organic dust applications.

Primary Benefit

Low impact on factory planning:

- Very small safety distance

- No external hazardous zoning required

- Not restricted by existing hazardous zoning

- NFPA 68 compliant

Certifications & Approvals

ATEX EN16009 certified upon request

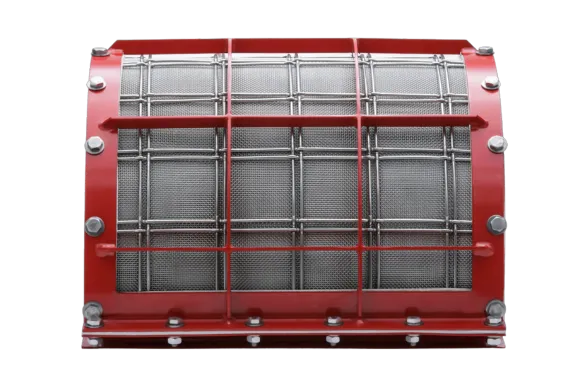

FlamQuench II

Function

Suited for metal dust applications and for corrosive or food production environments, due to full stainless steel execution.

Primary Benefit

Low impact on factory planning:

- Very small safety distance

- No external hazardous zoning required

- Not restricted by existing hazardous zoning

- NFPA 68 compliant

Certifications & Approvals

- FM Approved

- ATEX certified upon request

FlamQuench™ III SQ

Function

General purpose, cost-effective flameless venting device for fine, coarse, fibrous and melting organic dust applications.

Primary Benefit

Similar usage to FlamQuench II SQ; however, removes Particle Retention Screen to improve its venting efficiency, resulting in smaller and/or fewer required flameless devices.

Certifications & Approvals

ATEX EN16009 certified upon request

EleQuench

Function

Designed to protect against dust explosions in bucket elevators.

Primary Benefit

Low installation cost due to:

- Compact design with sizes that fit elevator legs

- High venting efficiency

Certifications & Approvals

- NFPA 68 compliant

- ATEX certified upon request

GEX

Function

Designed to protect against explosions in exhaust system of gas-fuelled engines, especially in manned areas or marine applications.

Primary Benefit

Unequalled, leak-free service life in high temperature, cyclic pressure and vibrations existing in gas engine exhaust piping.

Certifications & Approvals

- NFPA 68 compliant