Data Center Fire Hazards

The threat of smoke and fire damage to data centers is constant. Reaction time is crucial. Fike’s fire releasing panels generate highly accurate information and control suppression systems, voice evacuation systems, security systems and more. Fike fire suppression offerings include comprehensive water and chemical agents with the most well-regarded dispensing mechanisms available.

Server Rooms & Subfloors

Combustion in a server room may occur from a variety of sources, including a faulty hard drive, an electrical short or malfunctioning overhead lights. In the subfloors below, electrical malfunction from a cable or wire can cause a fire in the space and subsequently into the server room above.

Control Rooms

Common hazards in control rooms are the result of electrical fires caused by computer hardware and controls.

Uninterrupted Power Supply Rooms

UPS rooms possess several potential fire hazards, including faulty wiring which may produce electrical arcs or a malfunctioning battery which may offgas explosive hydrogen into the room.

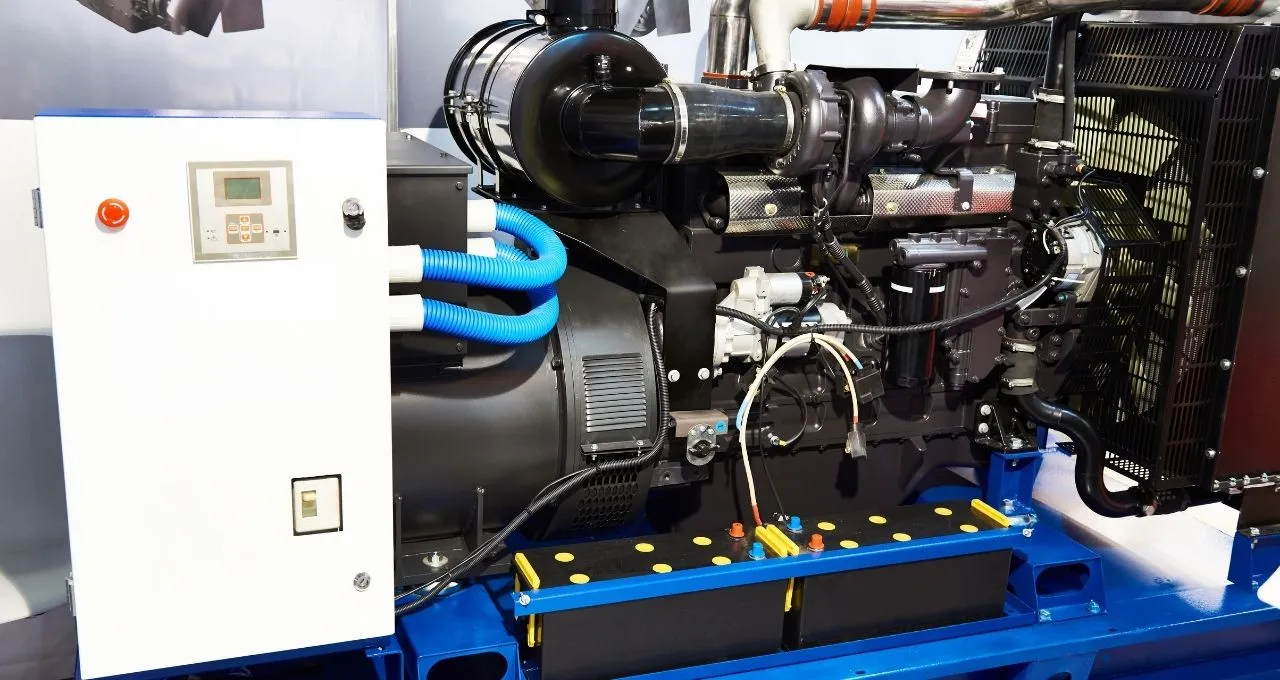

Diesel Engines

Fuel leaks are common in diesel engines and can quickly ignite if reached by an ignition source.

What does NFPA 75 say about ...

- Gaseous Agents

-

The use of gaseous agents provides the potential for automatic fire suppression in the incipient fire stage so that the information technology system can continue to perform its mission with little or no interruption. Where coupled with a well-designed early warning detection system, the gas can be automatically released in the early stages of a fire scenario and, being three dimensional, it will penetrate all portions of the space protected, including internal volumes of key components of the system when they are ventilated from the room. Thus an operator does not have to be present or, if present, does not have to determine if and where the fire is occurring and how to deal with it. Gaseous agents fall into the following general categories: inert gasses and chemical agents. (D.1)

- Concentration Levels

-

Total flooding agents are effective when the gas envelopes the protected equipment at the proper concentration, a minimum concentration is held until the ignition source is removed, and any smoldering fire that remains after flame extinguishment is controlled. This statement generally means that the enclosure to be flooded needs to be enclosed as much as possible to retain the gas discharged. Integrity of the space protected can need verification and means taken to close off openings to ensure an adequate gas concentration holding time. (D.2)

If major concerns over potential fire loss of specific critical data or equipment or serious interruption to operations cannot be resolved or alleviated by equipment redundancy, subdivision of the ITE area, or use of leased facilities, automatic gaseous agent total flooding might be the only feasible approach to handling an incipient fire situation with an acceptable minimum amount of damage. At the same time, this sophisticated protection approach requires that all environmental design criteria - for example, damper closure, fan shutdown, and sealed openings - be carefully maintained to ensure that the needed concentration for extinguishment will be achieved. (A.9.4.1)

- Subfloors

-

Where a gaseous fire extinguishing system is provided only under a raised floor, the gaseous system shall be either carbon dioxide or an inert gas. (9.1.1.5)

Where a clean agent fire extinguishing system is provided to protect the space above the raised floor, the space under the raised floor shall be simultaneously protected by the clean agent fire extinguishing system. (9.1.1.6)

The use of carbon dioxide systems for the protection of spaces beneath the raised floor is discussed in section B.5 of NFPA 12 wherein it is pointed out that the design of such systems requires compensation for leakage and provision for a soft discharge to minimize turbulence and agent loss through perforated tiles. These same concerns exist for other inert gas clean agent systems installed in accordance with NFPA 2001. Since these spaces are usually of a very limited height, this type of fire suppression system might be easier to design and install than sprinklers. (A.9.1.1.3)

- Detection

-

Automatic detection equipment shall be installed to provide early warning of fire. (9.2.1)

Automatic detection systems shall be installed to provide early warning of fire in the following locations:

- At the ceiling level throughout the ITE area.

- Below the raised floor of the ITE area containing cables.

- In the exhaust/return air stream where aisle containment systems are used.

- In the return air stream where the above ceiling area is used as a return air plenum (9.2.2).

- Smoke Detection

-

Where a smoke detection system is installed for the primary purpose of summoning responsible people to the presence of a small ITE fire or electrical event that produces smoke, the system should be arranged with high sensitivity and close spacing to achieve response to low-density products of combustion suspended in air with reasonable stability and tolerance of the environment. (A.9.2.2)

Where a smoke detection system is installed for the primary purpose of initiating the release of a fire suppression agent into an ITE area, the system should be arranged with low sensitivity, spacing less than listed spacing, and should include a form of logical confirmation of the presence of products of combustion to assure that a single indication does not release the agent. (A.9.2.2)