ValveGuard - Relief Valve Protection

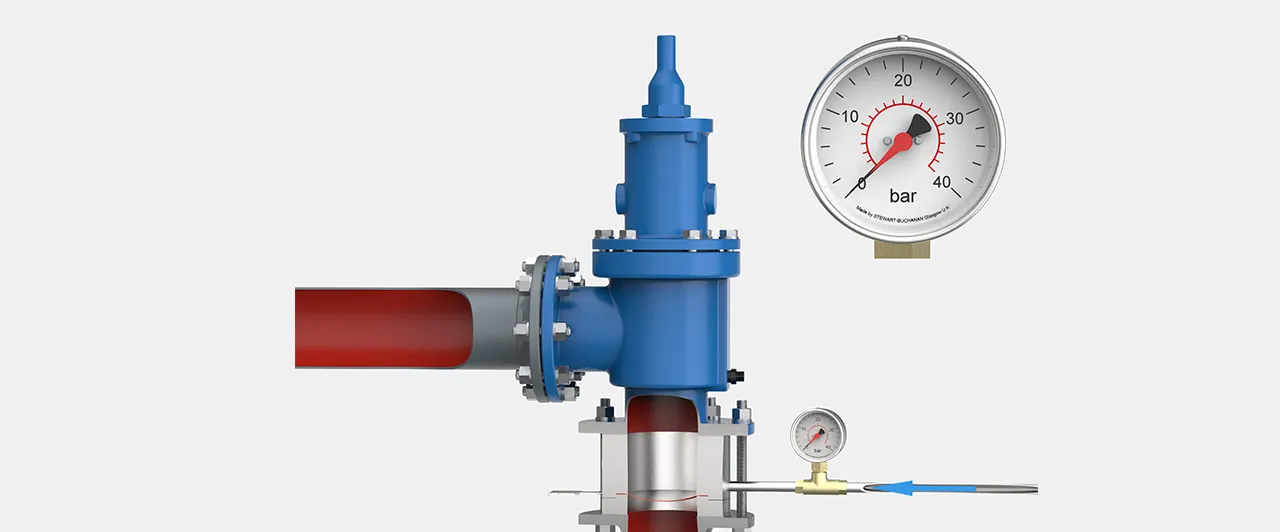

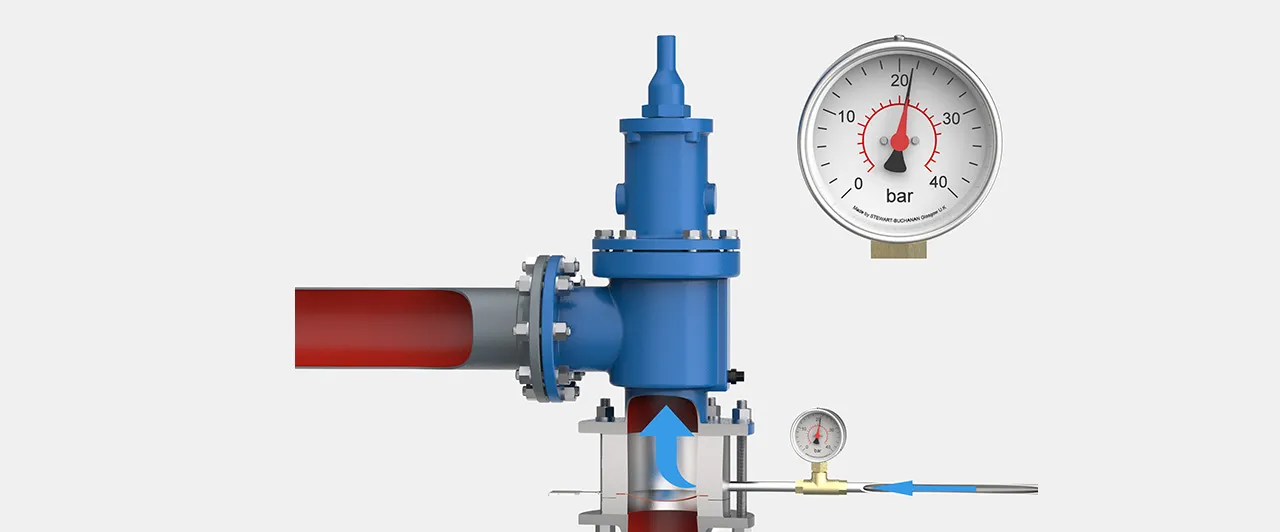

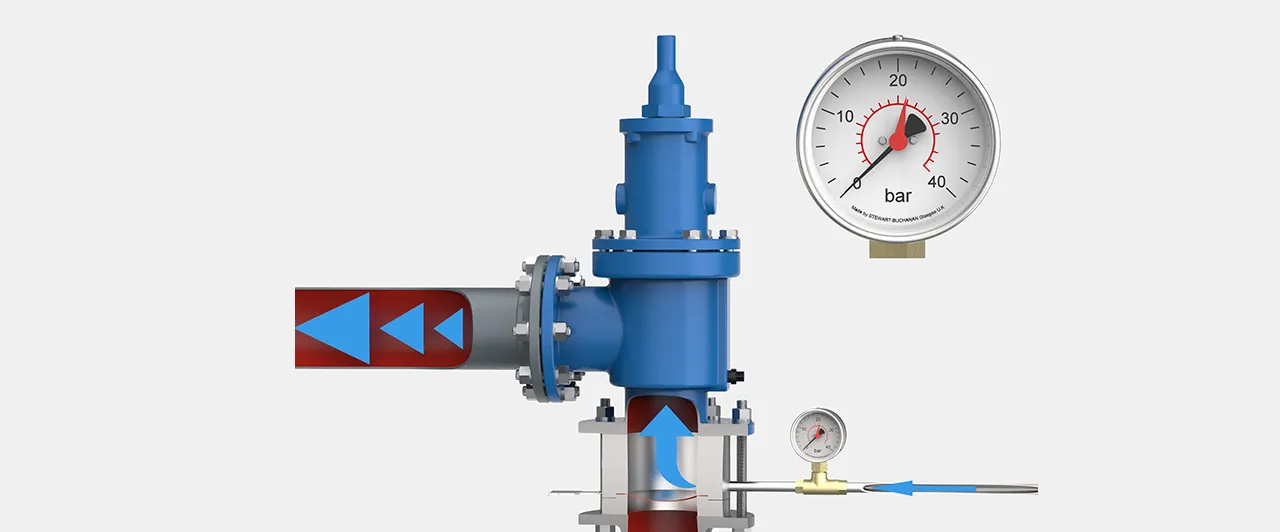

Why Isolate Your PRV With A Rupture Disc?

Using a corrosion-resistant rupture disc to isolate your PRV from corrosive process media prolongs the PRV's lifespan and allows you to use a standard carbon steel PRV valve and trim.

API Standard 527 calls for a maximum PRV seat leakage rate for metal-seated PRV's of 1.5 standard cubic feet. The leakage rate of rupture discs can be over 100 times lower to effectively reduce fugitive emissions.

Installing a rupture disc in series with your PRV will protect it against product build-up and polymerization. It also allows the PRV to be tested, which is a common maintenance requirement, without removing it from the process

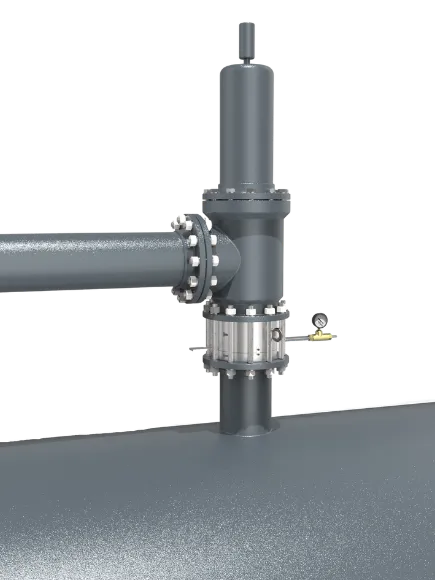

Compare & Save With ValveGuard

Initial Cost

Use a carbon steel valve and corrosion-resistant rupture disc to lower initial PRV investment.

Cost Of Ownership

Reduces maintenance intervals, allows for in-situ testing and prevents unplanned downtime to effectively lower the overall PRV cost of ownership.

Leakage Costs

Using a rupture disc in series with a PRV eliminates leakage, reducing product loss and cost of fugitive emissions.